Making a Bandsaw Box

Bandsaw boxes make for a neat project if you have the tools. The requisite tool here, of course, would be a bandsaw. I used my Rikon 10-324. To make a bandsaw box, you basically take a large block of wood and cut a box with drawers out of it in some sort of interesting shape. This past Christmas, I made two of them as gifts.

Selecting the Wood

I had some leftover maple and bloodwood from another project on hand. The bloodwood was a particularly vibrant red, and I figured it would go well with the maple. Really any wood could be used for a bandsaw box, even pine, but naturally you want to pick something with nice grain, figure, and color.

You can also laminate several pieces together, so this is a great way to make use of small scraps and cutoffs from other projects.

Design

Now you need to pick out a design. This goes hand in hand with selecting wood for the project, as you’ve got to limit your design to the size of the block available. In this case, I knew my wife wanted a funky dresser-looking box, so I sketched out something similar based on designs I found online.

After sketching half of it, I folded the paper in half and cut it out, to ensure it would be symmetrical. Note that this isn’t a requirement, as bandsaw boxes are frequently asymmetrical. Just make sure it has some kind of bottom to stand up on.

Laminating the Wood

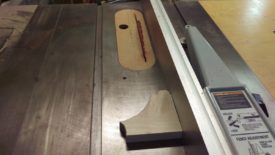

Since I’m using a couple of thinner boards, I need to glue them together to make a solid block. In woodworking, this is referred to as laminating. Once the boards were jointed and planed, I cut them into consistent pieces using my small table saw sled.

This could have also been done on the bandsaw. Most importantly, make sure the pieces to be laminated are all very flat, to eliminate gaps from the final block.

Titebond 2 is my go-to general purpose woodworking glue. The pieces got a nice even coat, and then I used more clamps than probably necessary.

Cutting the Outside

Once you have a solid block of wood, you can cut the outside of the box. I used some spray adhesive, but glue stick or similar works as well.

Once the pattern is pasted on, you can cut the outside of the box. I used a 1/4″ 10tpi blade. Technically, for wood this thick, it would be appropriate to use a more coarsely-toothed blade, like 4tpi. I found that that results in a lot of sanding afterwards, though, and the finer-toothed blade seemed to handle the thick material just fine as long as I went slowly enough.

Sanding the Outside

I find it easiest to go ahead and do the bulk of the sanding on the outside at this point, while it’s still a solid block of wood. This isn’t a final sanding, as you’ll make two new glue joints later on. I just like to knock down the majority of the bandsaw marks.

One of these little drum sanding kits can speed up sanding inside of curves if you have a drill press but don’t have an oscillating spindle sander

. I used a kit like this with my Porter Cable drill press, which I highly recommended and is available from Lowes, but it’s recently gone up quite a bit in price.

A much cheaper tool that does a good job is a cabinet scraper. If you buy one, you should also grab a burnishing tool

to sharpen it with.

Cut Off the Back

Once the outside is acceptably smooth, the next step is to cut off the back of the box. This involves using the bandsaw to cut about a quarter inch slice as shown.

Cut the Drawers

Set the back of the box aside for now. Glue or draw the drawer shapes on to the main block and cut them out on the bandsaw. When cutting the drawers out, it is important to make one smooth pass. Go straight into the wood, cut the outline of the drawer, and stop the bandsaw. With the blade off, you can get the blade back out through the entry kerf.

Here is the box after cutting the drawers out. Note that there are two kerfs. Try to position them in a place on the box that will be somewhat hidden.

Gluing the Box Kerfs

with the drawers cut out, the box can be glued back together. The two bandsaw kerfs should be filled with glue and aggressively clamped to close them back up. Rubbing sawdust into the squeeze out helps to hide the kerf later on.

Cutting the Drawer Pieces

While the box kerfs dry, you can cut the drawer pieces. To start, the fronts and backs of the drawers need to be cut off as shown.

Once the fronts and backs are cut off, the middle of the drawers should be cut in a U shape, to form the storage space for the drawer. Once the front and back of each drawer is glued back on, the drawer will be complete.

Sanding and Assembling the Drawers

I find it helpful to sand the inside of the drawers now, before gluing up. It’s a lot easier to get the sander in the inside at this stage.

I went a little overboard, but painter’s tape before glue prevents squeeze out from staining the wood.

Once the glue dried, I peeled off the painter’s tape. The drawers are now assembled.

Sanding and Gluing the Box’s Back

I used the same basic technique to put the back on the main box. I also paid attention to the drawer kerfs in the box at this point, making sure they were adequately cleaned up and hidden.

Making Drawer Pulls

I chose to make D-shaped drawer pulls out of maple. To start, I took a piece twice as thick as I needed and cut out a shape I liked on the bandsaw. The excess material makes it easy to safely handle.

The table saw then takes care of cutting the big piece down into two smaller pieces, still attached to some excess material intentionally.

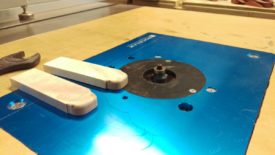

The router table with a roundover bit easily cleaned up the edges. I followed this with sandpaper.

Lastly, the handles are cut off from the excess material using a sled on the table saw.

And here are the pulls after gluing them on to the drawer. Note that the glue joint is cross grain to cross grain, which is very important. If the pulls were end grain, this wouldn’t stick nearly as well.

Final Sanding and Scraping

With everything glued up, the box is nearly done. A cabinet scraper will quickly knock down the ridge from the back of the box and any other places that don’t feel good to the touch. I also used an 1/8″ roundover bit on the front and back of both the drawers and the box itself. This also helps disguise any uneven gap between the drawers and the box.

Finishing

For projects like this, I have found spray lacquer to be a great choice. It dries quickly and builds up a durable, thick coat with a lot of gloss. Spray cans like this would be way too expensive to use for finishing furniture or something, but they work great for something this small.

Wrap-up

And here is the final product. I think the gloss from the spray lacquer really brings out the grain and colors in the maple and bloodwood.

Here is another box I made out of walnut, maple, and bloodwood. These boxes are easy to make and can be made in any design you can imagine, making them great gifts.

What size was the wood before glue up? I usually only have 1×6’s on hand. Which you know is less than that. Would like to see you show us how to do that. Thx.

Hi Michael – the nice thing about bandsaw boxes is that you can get creative with them and make them out of any material in basically any pattern. 1×6 lumber will work just fine – I would just laminate as many as you’d like to get your desired box size.

Laminating 6 pieces of 1×6 together like I glued up in the article would be a nice 4.5″ deep box. That would probably be a good start?