Drill Battery Power for a TS-100 Soldering Iron

For most soldering, I use a Hakko FX-888D that sits on my workbench. It’s fantastic, and I can’t recommend it enough. However, I also often have to do soldering away from the bench, typically for wiring a car or my trailer. To solve this, I ended up 3d printing an adapter to provide Milwaukee drill battery power for a TS-100 soldering iron.

Alternate Options

I initially got a Hakko FX-901. It had positive reviews, and was really cheap and easy. Unfortunately, when I tried to use it on my Mustang switched 12V power project, it simply wasn’t up to the task. I had to drag my soldering station out into the driveway, with a long extension cord. The 901 is only 6 watts, and this just isn’t enough wattage for most automotive soldering jobs. 18 gauge wire was a real strain with it.

I also looked into butane soldering irons, like a Portasol. These would doubtless have the power I wanted, but the thought of dealing with butane cartridges did not appeal.

What is the TS-100?

The TS-100 is a well-known soldering iron, along with the newer version, the TS-80

. They’re both standalone irons, rather than full soldering stations, but they have an integrated OLED and thermostat. They heat up quickly and maintain temperature properly.

Because the hardware design is open source, anybody can manufacture it. As a result, you can buy either one from the usual import electronics sources quite inexpensively.

TS-100 vs TS-80

The TS-80 is newer, so why didn’t I go with that? Well, in a word, power. The TS-80 maxes out at 9V at 2A, resulting in 18 watts of power. The TS-100 can operate on anything from 12V to 24V, and at 24V is rated for 65 watts. As a result, the TS-100 is better for soldering larger wires, and it can also easily run off of a typical drill battery, which is usually 18 to 20 volts.

Either of These vs Hakko Soldering Station

As an aside here, a lot of folks recommend these soldering irons over a traditional station like the Hakko FX-888d. I… disagree, to be polite. These irons are quite good for what they are, but in my opinion, they still don’t match having a 65 watt station with myriad T18 tips available. By contrast, the TS-100 and TS-80 tips are very expensive.

Plus, the station still simply has more power and heat capacity than the TS-80. Even the TS-100 doesn’t match it unless you manage to supply 24V power, which the average drill battery won’t do. So they’re good little irons for what they are, but I don’t agree with the rave reviews saying you’ll never need a station again. I love my Hakko. For a lot of soldering jobs, these open source irons can certainly get a lot done, though.

Making a Drill Battery Adapter

There are oodles of 3d printed battery to generic wire adapters for all sorts of tools. I have Milwaukee M18, but this would work fine for Dewalt, Makita, etc by substituting the correct adapter. To start, I printed this adapter from thingiverse. I won’t delve into that in this article, but if you don’t have access to a 3d printer, you can buy them on Amazon for about twenty bucks. I can’t speak to the quality though.

In any case, once the battery adapter is printed, you put spade terminals on two wires and put them in the holes, as shown. They should slot right in.

With the spade terminals where you want them, add a generous amount of two part epoxy from the back to hold them in place. I have found that I like JB Weld MinuteWeld because it has a cap design that actually allows it to be sealed and reused. Either way, let the epoxy fully cure.

The thingiverse link includes the back piece for the adapter pictured. I think it’s supposed to provide some strain relief, but I found that the wire didn’t route through it very easily. I chose to not bother using this piece and haven’t had a problem.

Wiring the Adapter

The TS-100 has a 5.5mm x 2.5mm DC barrel connector. This is somewhat common on certain laptop supplies, and if you have one, you can use it directly. To wire my iron, I ended up getting a package of female connectors and another one of male connectors

so I could wire things a few different ways. Essentially, I have short wires from a 12V car cigarette outlet power I had on hand, as well as the Milwaukee battery adapter. I also made up some “extension” wires, so I can mix and match depending on what I’m doing.

For one of the extension wires, I used some nice 3-core silicone wire I found cheaply on Banggood. Note that two core would have been fine. I would have preferred to order from somewhere else, but Banggood was the only place I could find this wire inexpensively.

Rather then go over each soldered connection individually, this picture shows an overview of the whole setup. I put a male connector on short wires from the Milwaukee adapter. One 6 foot “extension” has a male connector on one end of some speaker wire and a female on the other. I did another one of these using the nice silicone wire; this extension is for nearer to the soldering iron, because the silicone jacketed wire is much more flexible. Lastly, I put a male connector on the 12V car adapter. The point is, mix and match to your heart’s content.

Stretching the Barrel Connector Housing

The Banggood 3 core wire was just slightly wider than these barrel connector housings. One trick I found was to use an appropriately-sized screwdriver to force the plastic housing to be just a bit wider. Doing this, I was able to slip the connector housing over the outer jacket as shown for a cleaner install.

Soldering a Male Barrel Connector

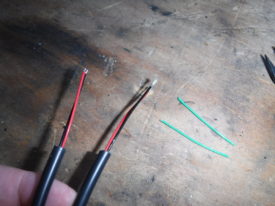

To attach one of these connectors, strip the wiring first. Only two wires, positive and negative power, are required. As such, I clipped the third wire in the 3-core silicone wire short, as shown.

This picture shows the 12V car power outlet in progress. I unscrewed the black plastic connector housing and slid it down the cable. If the cable is thin enough, it can be pulled on from the other end.

At this stage, I would also slide some heat shrink down each wire.

Hopefully, the picture is good enough that you can see the barrel connector has two tabs. Each of them has a very small hole to thread the wire through.

The ground wire goes through the longer tab on the outside. Once through, some small pliers will easily crimp everything down to hold it in place.

This shows the positive wire in place as well. I got them both lined up and then soldered.

Here both wires are soldered, with heat shrink applied. I didn’t put heat shrink on the ground wire for this connection, but I probably should have.

After solder and heat shrink, I screwed the plastic connector housings back on. Lastly, I pulled the outer wire jacket back up and taped it to seal.

Repeat for all male connections. On the three core wire, I added some heat shrink to neaten it up.

Soldering a Female Barrel Connector

The female barrel connectors are very similar, two with slight differences. The inner connector has this cup shape, as opposed to the tab style of the other connector. This requires putting a blob of solder in the cup and on the wire, then melting them together.

The second difference involves the female connector’s assembly. The middle pin can float around when heat is applied and get misaligned. To combat this, I have simply plugged a male connector in, visible in the picture. This will hold the positive pin in place even if it heats up.

On a relevant note, the helping hand I used was cheap and very helpful for holding everything in place.

This is just before soldering the center pin. I have slid heat shrink on both wires, put the barrel connector housing down the outer wire jacket, and crimped the ground in place. I have also applied a blob of solder to the pin and tinned the red wire.

To solder the positive wire, I simply heated the tinned wire against the blob of solder on the connector until they sank together firmly.

This picture shows the ground wire soldered more clearly.

After I took out the male connector, I applied some heat shrink. The ground wire heat shrink ended up being a little bit snug and tearing on some extra solder, but oh well.

Here is the final extension wire. The male end plugs into the TS-100, and the female end goes to a male connector on the battery or 12V car power. The silicone jacketed wire is much more flexible than standard, so it doesn’t pull on your hand when you’re trying to carefully solder something.

Wrap-Up

I thought I would show the overview shot one more time. I ended up making a battery adapter for the Milwaukee M18 battery with a male connector on a short wire. The long section of speaker wire has both a male and a female end to act as an extension cord. The silicone wire also has a male and a female end and is used to provide a flexible connection to the TS-100. Lastly, there’s even a 12V power adapter for use in the car. It should be noted that you should not solder something plugged to the car’s battery while powering the iron from the car battery.

This is the setup I use the most. Drill battery, adapter, flexible cord, and TS-100. This setup has proven extremely handy for soldering in the car or anywhere away from my work bench, while handling wire down into the 10 to 12 gauge range without issue.